Back then, bedtime begins with a generous smear of bedak sejuk. As much as we don’t want to be seen in such appearance, the powder’s cooling sensation and pleasant aroma simply won us over.

And our grandmother, somewhat the brand ambassador of bedak sejuk, never stops vouching for its skin benefits. Add to that the joy of impersonating Casper and squealing “Boo!” to no one’s attention.

So, when the opportunity to visit a traditional powder factory presented itself, also the last of its kind, I wasted no time!

Stirred up with childhood memories, I made my way to Perniagaan Bedak Sejuk Lean Seng in Balik Pulau.

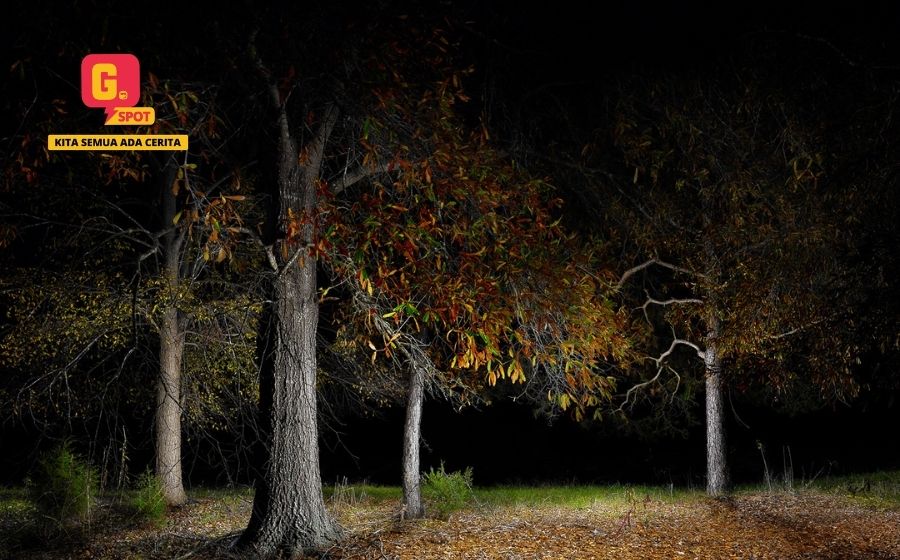

First to impress was the pulse of the town as it felt like a time capture of Penang before mass development kicked in. Serenity touches the soul with the sceneries of rolling hills, lush plantations and tilted wooden houses.

The people, unpretentious and welcoming, made my navigation a bliss. So did a bag-full of banana and sweet potato fritters.

The factory is sited inside a fishing village with boats gently bobbling over a calm creek and fishing nets filtering rays of sunlight in local coffee shops. Hospitality is so deeply ingrained among the villagers that I was repeatedly told of walking on the right route despite my doubts.

There were hardly traces of smoke coming off chambers, production sound or even harden mud trails of lorries. Rather warm afternoon breeze enticed the need of bedak sejuk, wilted leaves crackled beneath my steps and birds were chipping without break, perhaps complaining an intruder is coming.

A few steps later, at an entrance, rows of broken rice were dried under the hot sun. The outlook of the property blurs the lines between a workshop and a home that has withstood the test of time.

As I entered, two brothers, Mr Yeoh Siong Huat and Mr Yeoh Seong Chin, greeted my arrival while arranging bottles and trays filled with the cooling powder. Vintage lanterns, rattan baskets and makeshift wooden planks further added to the nostalgic vibes.

The business was started by their late father, Mr Yeoh Keng Beng, in the year 1975 and the sons have spent their formative years in it.

Today, Mr Siong Huat has taken over the mantle upon Uncle Yeoh’s passing five years ago. The production still sticks to its humble roots as the ingredients are all-natural and the processes are largely handmade.

While our conversations underlined quality control and painstaking processes, the underlying value is reputation.

Mr Siong recalls that his father’s main mantra was to stick to the basics. The founder had spent years perfecting the formula of bedak sejuk and the last thing he wants is someone making modifications.

He explains that his father even turned down plastic bottles despite it being cheaper and easily available because being eco-friendly is part of the equation. Similarly, shafts of sunlight should never be substituted by any forms of drying machines.

The list went on, but it rather brought smiles on his face.

“My father was a very hardworking man. Apart from bejak sejuk, he also made belacan and reared pigs to support the family. But it was the powder that earned much of the positive responses,” said the equally hardworking gentleman.

When asked, “Will there be any major changes in future?”

He smiled and shook his head in a manner which translated to “no”.

“Maybe some natural ingredients for a variety of aromas,” he hinted with hopes.

Sometimes, the most humble-looking products bear the most back-breaking processes.

Firstly, broken rice sourced from Kedah is soaked in water for approximately a month for fermentation. The water is changed several times in between before the rice is blended to a paste-like texture, which is then filtered and hung out to dry for long hours.

The paste is mixed with water to achieve a semi-thick consistency and then ladled over a handmade mould. Its gently mashed out with a slab onto sheets to get its mini Hersey’s chocolate-like shape.

Mr Siong genially uttered, “Initially we used to squeeze out one bead at a time with piping bags.”

As is sometimes the case in most small-scale factories, I was offered a hands-on experience. Despite the simple and straightforward technique, the slightest stutters of my hands resulted in uneven beads.

Only after two more attempts, I got a satisfactory nod by the master himself. Through him, I could look upon the attentiveness passed down by Mr Yeoh.

The tiny pearls are then layered over wooden planks and sun-dried for two hours and left in the room overnight.

The drying process is repeated for four to five days, depending on the weather, as there should be zero presence of water in the powder.

Finally, the bedak sejuk is mixed with smatterings of pandan leaves and packed into glass bottles to be sold.

The key here is the fermentation process that unveils the cooling properties of the rice. While old-timers have gone as far as covering their whole body with the powder due to its fresh aftereffect, it also gives the skin a smooth and silky feeling.

The fermented powder also reduces pimples, peels away dead skins and helps to combat chickenpox rashes. Now you understand why our grandparents always debunk the myth of using costly cosmetics to get the job done.

However, the brothers are gradually building the bridge through workshops. The hands-on program is gaining momentum among students and team-building participants, as many combine it with a day trip to Balik Pulau.

Regardless, Mr Siong isn’t too caught up with numbers and analytics. His aim of making someone’s day or sleep a little better, one bottle at a time, may sound simple but it underlines his love for his father and the business itself.

More often than not, the takeaway point is to support local products. But in a bigger picture, it seems like the social blanket of commercial brands has eclipsed the genuine efforts of traditional trades to survive.

With digital communication being a powerful tool today, spreading the word can be as simple and comfortable as slathering bedak sejuk.

And our grandmother, somewhat the brand ambassador of bedak sejuk, never stops vouching for its skin benefits. Add to that the joy of impersonating Casper and squealing “Boo!” to no one’s attention.

So, when the opportunity to visit a traditional powder factory presented itself, also the last of its kind, I wasted no time!

Not your average factory visit

Stirred up with childhood memories, I made my way to Perniagaan Bedak Sejuk Lean Seng in Balik Pulau.

First to impress was the pulse of the town as it felt like a time capture of Penang before mass development kicked in. Serenity touches the soul with the sceneries of rolling hills, lush plantations and tilted wooden houses.

The people, unpretentious and welcoming, made my navigation a bliss. So did a bag-full of banana and sweet potato fritters.

The factory is sited inside a fishing village with boats gently bobbling over a calm creek and fishing nets filtering rays of sunlight in local coffee shops. Hospitality is so deeply ingrained among the villagers that I was repeatedly told of walking on the right route despite my doubts.

There were hardly traces of smoke coming off chambers, production sound or even harden mud trails of lorries. Rather warm afternoon breeze enticed the need of bedak sejuk, wilted leaves crackled beneath my steps and birds were chipping without break, perhaps complaining an intruder is coming.

A few steps later, at an entrance, rows of broken rice were dried under the hot sun. The outlook of the property blurs the lines between a workshop and a home that has withstood the test of time.

As I entered, two brothers, Mr Yeoh Siong Huat and Mr Yeoh Seong Chin, greeted my arrival while arranging bottles and trays filled with the cooling powder. Vintage lanterns, rattan baskets and makeshift wooden planks further added to the nostalgic vibes.

Traditional roots are the bedrock of the business

The business was started by their late father, Mr Yeoh Keng Beng, in the year 1975 and the sons have spent their formative years in it.

Today, Mr Siong Huat has taken over the mantle upon Uncle Yeoh’s passing five years ago. The production still sticks to its humble roots as the ingredients are all-natural and the processes are largely handmade.

While our conversations underlined quality control and painstaking processes, the underlying value is reputation.

Mr Siong recalls that his father’s main mantra was to stick to the basics. The founder had spent years perfecting the formula of bedak sejuk and the last thing he wants is someone making modifications.

He explains that his father even turned down plastic bottles despite it being cheaper and easily available because being eco-friendly is part of the equation. Similarly, shafts of sunlight should never be substituted by any forms of drying machines.

The list went on, but it rather brought smiles on his face.

“My father was a very hardworking man. Apart from bejak sejuk, he also made belacan and reared pigs to support the family. But it was the powder that earned much of the positive responses,” said the equally hardworking gentleman.

When asked, “Will there be any major changes in future?”

He smiled and shook his head in a manner which translated to “no”.

“Maybe some natural ingredients for a variety of aromas,” he hinted with hopes.

Time-consuming and tedious procedures

Sometimes, the most humble-looking products bear the most back-breaking processes.

Firstly, broken rice sourced from Kedah is soaked in water for approximately a month for fermentation. The water is changed several times in between before the rice is blended to a paste-like texture, which is then filtered and hung out to dry for long hours.

The paste is mixed with water to achieve a semi-thick consistency and then ladled over a handmade mould. Its gently mashed out with a slab onto sheets to get its mini Hersey’s chocolate-like shape.

Mr Siong genially uttered, “Initially we used to squeeze out one bead at a time with piping bags.”

As is sometimes the case in most small-scale factories, I was offered a hands-on experience. Despite the simple and straightforward technique, the slightest stutters of my hands resulted in uneven beads.

Only after two more attempts, I got a satisfactory nod by the master himself. Through him, I could look upon the attentiveness passed down by Mr Yeoh.

The tiny pearls are then layered over wooden planks and sun-dried for two hours and left in the room overnight.

The drying process is repeated for four to five days, depending on the weather, as there should be zero presence of water in the powder.

Finally, the bedak sejuk is mixed with smatterings of pandan leaves and packed into glass bottles to be sold.

Benefits of bedak sejuk

The saying “less is more” is rather overlooked when it comes to skincare.The key here is the fermentation process that unveils the cooling properties of the rice. While old-timers have gone as far as covering their whole body with the powder due to its fresh aftereffect, it also gives the skin a smooth and silky feeling.

The fermented powder also reduces pimples, peels away dead skins and helps to combat chickenpox rashes. Now you understand why our grandparents always debunk the myth of using costly cosmetics to get the job done.

A generational gap?

To the older generation, the rice-based powder is a perennial pick but it sees a dip in demand among youngsters.However, the brothers are gradually building the bridge through workshops. The hands-on program is gaining momentum among students and team-building participants, as many combine it with a day trip to Balik Pulau.

Regardless, Mr Siong isn’t too caught up with numbers and analytics. His aim of making someone’s day or sleep a little better, one bottle at a time, may sound simple but it underlines his love for his father and the business itself.

More often than not, the takeaway point is to support local products. But in a bigger picture, it seems like the social blanket of commercial brands has eclipsed the genuine efforts of traditional trades to survive.

With digital communication being a powerful tool today, spreading the word can be as simple and comfortable as slathering bedak sejuk.